Lab Padder

Lab Padder, a floor type padding mangle for dyeing, finishing and Impregnating. We provide the professional vertical padder, please contact us if you are interested in it.

Description

Model: TD122

Brand: TESTEX

Application

Lab Padder, padding mangle is used for dyeing, finishing and impregnating.

The roller of lab textile padder is made of quality NBR; good flexibility ensures long-life; whole machine is made of high quality stainless steel. The main components are all the best in the world. The lab padder is equipped with emergency button and a knee pedal to stop the machine operation. Air compressor can be supplied on request.

Only logged in customers who have purchased this product may leave a review.

Specifications

- Working position Vertical

- Working width 400mm

- Rollers 130mm, with 70 ~ 80 shore hardness

- Working speed 0 ~ 10m/min

- Roller’s loading 1 ~ 0.7Mpa

- Padding rate 30 ~ 90%, adjustable

- Equipped with 2 pressure valve, each side of pressure is adjustable

- All panels are made of stainless steel

- Equipped with Chemical trough and a shower for cleaning

Weight

| 165 kg |

Power

| 220/110 V | 50/60 Hz | 0.4-0.7 Mpa |

Dimensions

| Width: | 840 mm | Depth: | 740 mm | Height: | 1100 mm |

| 34 inch | 30 inch | 44 inch |

RELATED PRODUCTS

IR Lab Dyeing Machine

Lab Calender

Light Box – Judge QC

Portable Spectrophotometer

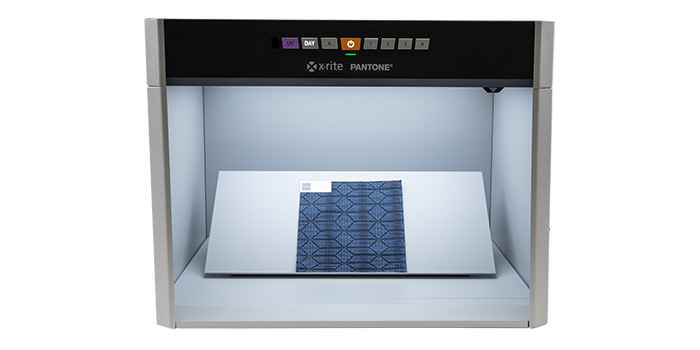

X-Rite Judge LED Light booth (H&M L31-9)

Judge LED – Rapid, Accurate, and Consistent Color Evaluation

The Judge LED Light Booth is engineered to deliver fast, reliable, and repeatable color assessments across the entire supply chain. Featuring instant warm-up technology, user-friendly push-button controls for effortless switching between light sources, and precisely calibrated intensity settings, it ensures stable chromaticity for professional-grade results every time.

Reviews

Clear filtersThere are no reviews yet.